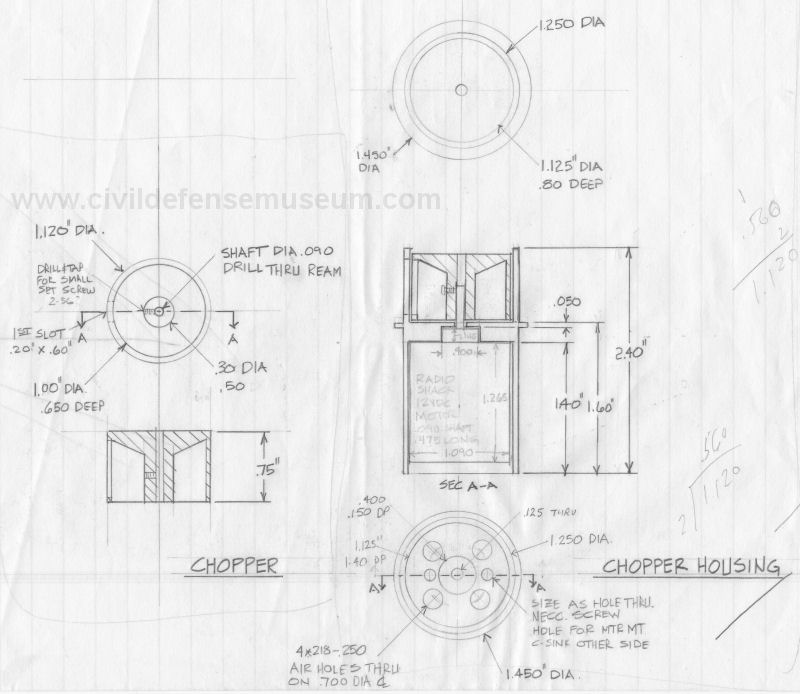

I'll dig it out and if it makes any sense at all I'll scan it and post it.

That's almost impossible to answer without a long dissertation.Can you tell me about the challenges of getting this portion working?

I remember I started with the motor which I got from Radio Shack. I was thinking about a chopper

of about an inch in diameter I just went in and got that motor without thinking much about it other

than I guessed it would be about the right size. It's this motor or very similar to this motor....

http://www.radioshack.com/radioshack-su ... INyiGeROK8

I would have to look again but I think the radio shack number is different than the original motor I got.

I ended up putting a load resistor in the chopper circuit to brink the voltage/rpm down to the right pitch.

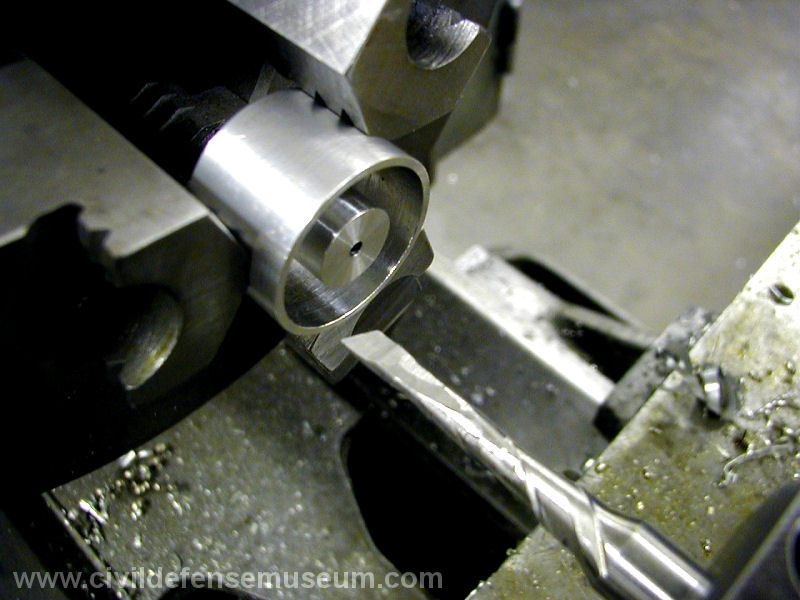

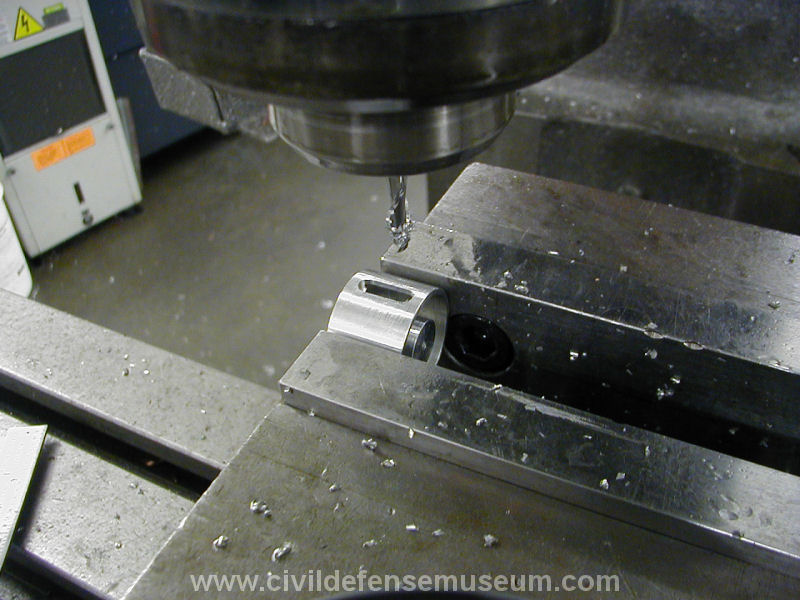

I made the stator first mainly paying attention to getting the motor to slip fit into the bottom of the stator.

I got lucky in that the first motor I got was fairly well built in that if fit well and I didn't have any bad concentricity

issues when I put the chopper onto the motor shaft.

The first chopper I made was only 4 port as you can see in the pic above.

That was really just a test chopper.

I need to go do something now so I'll look for that dimension sketch and

try to find some of the pics I took while I was making the chopper.