Thanks Bryan for the Bar Grille 1000 from Fort Worth!!! Here's what I have found so far...

The chopper looks really good! I guess the horn gasket was blown out so it leaked into the

chopper opening slot and magnesium oxidized the chopper right at the slot. It was only surface oxidation

and cleaned off with scotchbrite! The bearings are really smooth so I'll leave them in for now. The windings

and armature all look really good as well. Collector ring wires are ok at the rings. I should be able to

strip back enough at the tube seal to run the chopper. I had to cut the heads off of the screws to get the motor

out. One screw came out with vise grips and the other two are stuck so I am letting them soak.

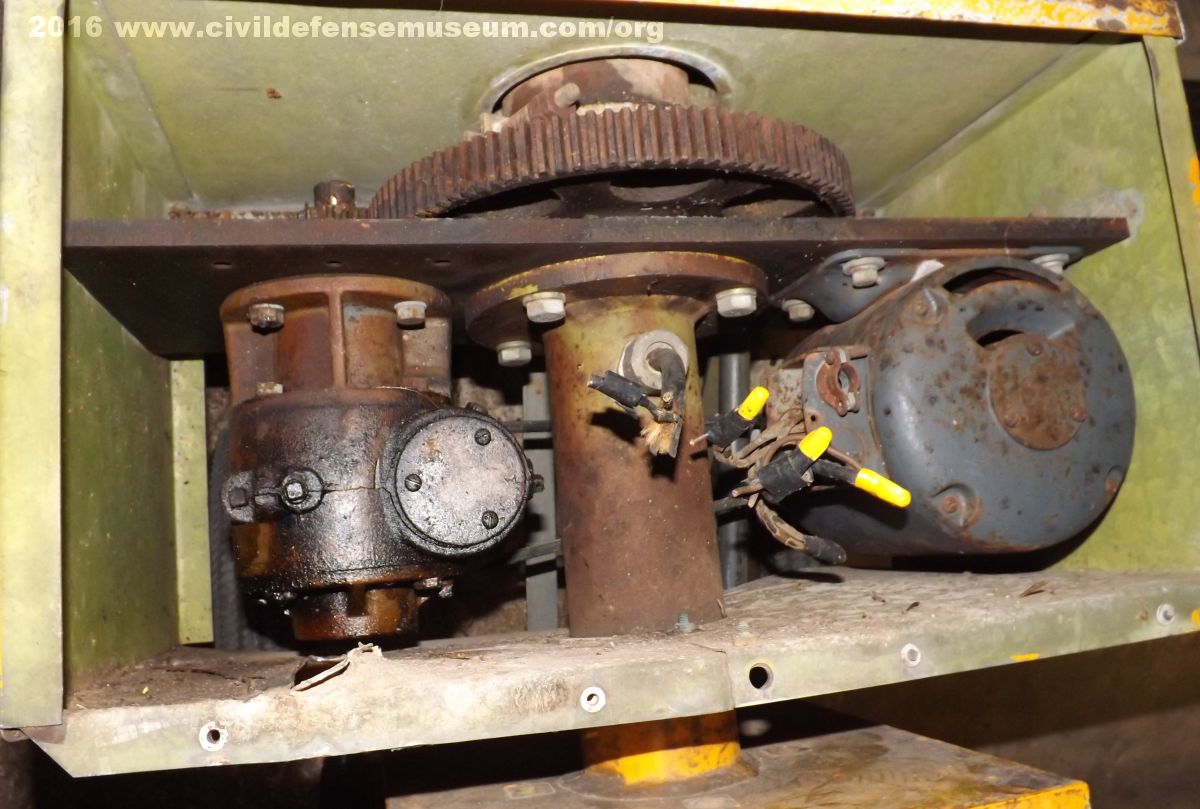

Looking at the ancient gear reducer is interesting. There is still gear oil in it! The thing shifted over

in the truck when I made my first turn and oil started running out of the vent. You can sort of see the rotator motor/gear

reducer plate is also drilled and tapped for an Abart type reducer.

The horn support actually unbolted easily. I'll ask the old-timer at work his opinion on

fixing the cracks in the horn. Hopefully that won't be a big deal.

Looking at these bars close up I'm wondering if they are merely reinforcement that they

thought the horn needed originally. I can't think of any other reason for them.