Page 1 of 1

Re: Thanks Bryan!!! Initial B.G.1000 findings.

Posted: Mon May 02, 2016 9:50 am

by SuperBanshee

Those are some interesting photos. In regards to the bar shaped grilles, they were basically reinforcements. Federal didn't want the horn to warp about as this would compromise sound output entirely - the horn has to be largely free of any warped spots to project sound effectively.

But then it became obvious the thicker metal panels used for the horn were already strong enough to avoid such severe warping, so they changed the grilles out for the debris-resistant mesh screen by 1955. I don't think the grilles were ever meant to keep out debris.

Re: Thanks Bryan!!! Initial B.G.1000 findings. Bolt removal ordeal.

Posted: Fri May 06, 2016 5:44 am

by CDV777-1

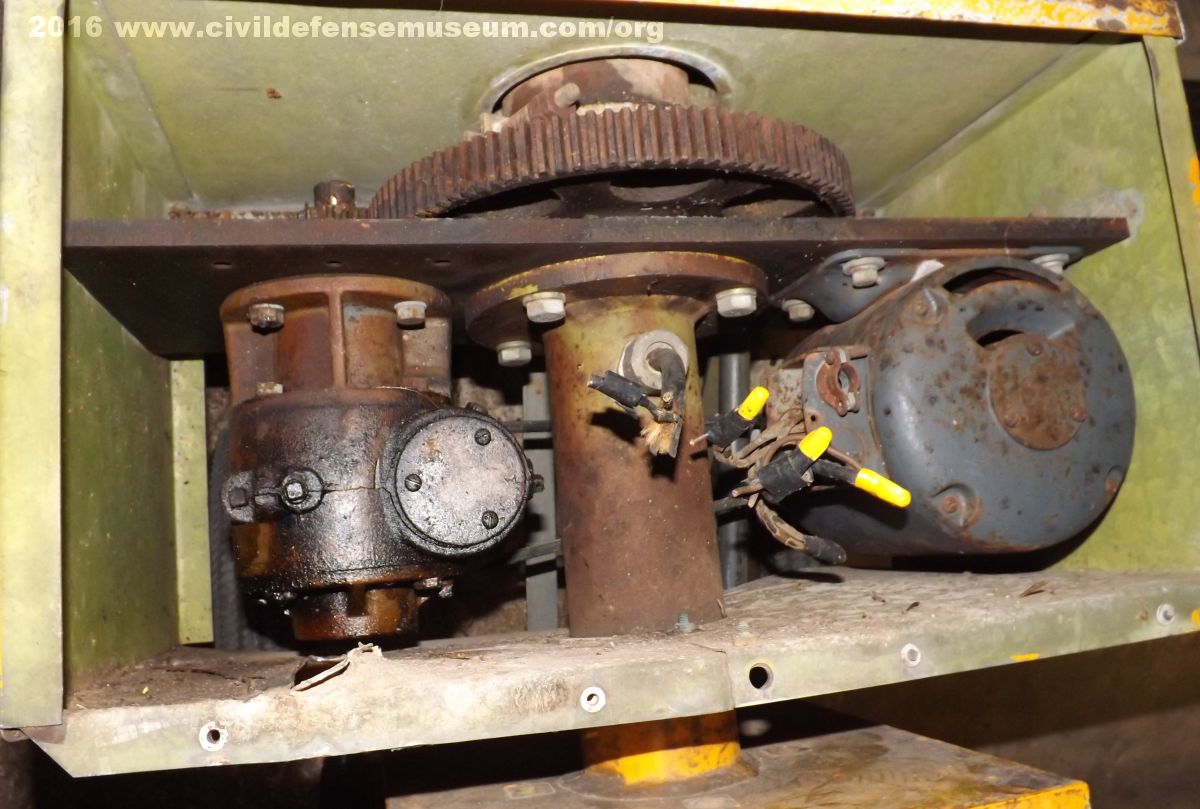

Well soaking the bolts didn't work. The chopper had stainless round head slotted head screws. One was missing and I was able to get one out after cutting the heads off of them with a Dremel with a little cut-off wheel. Out of all the old rotten Thunderbolts I have messed with I have never had a chopper bolt break until now. I soaked the remaining two and heated them with a propane (all I have) torch (not hot enough) and I did get one to move 3/4 of a turn but then it broke off after a half hour of manipulating it back and forth. Here's a pic of what I came up with to try to get the bolts out. A guy at work has a mag drill so I made a steel plate out of scrap and held it in place with two flat head 1/4-20 screws which were screwed into the good bolt holes.

Well soaking the bolts didn't work. The chopper had stainless round head slotted head screws. One was missing and I was able to get one out after cutting the heads off of them with a Dremel with a little cut-off wheel. Out of all the old rotten Thunderbolts I have messed with I have never had a chopper bolt break until now. I soaked the remaining two and heated them with a propane (all I have) torch (not hot enough) and I did get one to move 3/4 of a turn but then it broke off after a half hour of manipulating it back and forth. Here's a pic of what I came up with to try to get the bolts out. A guy at work has a mag drill so I made a steel plate out of scrap and held it in place with two flat head 1/4-20 screws which were screwed into the good bolt holes.

Here it is before drilling the second bolt out. The hardest part of drilling out a bolt is getting it right on center. If you can do that you can drill with a small drill through the bolt then drill with a drill the same size as the minor diameter of the thread and you can peel the threads right out. You really have to have a mill to get it just right but I thought I would try this mag drill/plate deal because it would be such a pain to figure out how to hold the chopper tube in place on a mill. I hit the first bolt right on center and the threads of the bolt come out through the chopper bolt block wrapped around the drill bit.

Here it is before drilling the second bolt out. The hardest part of drilling out a bolt is getting it right on center. If you can do that you can drill with a small drill through the bolt then drill with a drill the same size as the minor diameter of the thread and you can peel the threads right out. You really have to have a mill to get it just right but I thought I would try this mag drill/plate deal because it would be such a pain to figure out how to hold the chopper tube in place on a mill. I hit the first bolt right on center and the threads of the bolt come out through the chopper bolt block wrapped around the drill bit.

Here's a closer view of the second bolt. I didn't have the same luck on this one because I didn't grind the bolt completely flush with the block. The drill walked over a little and there was some of the bolt thread left after I drilled it out. I still have my 1/4-20 helicoil set I used to fix a chopper upper bearing retainer on my first thunderbolt restoration so I drilled it with the helicoil drill and that drill followed the original hole and cleaned everything out. Now I just have to helicoil it and do a chopper test!!

Here's a closer view of the second bolt. I didn't have the same luck on this one because I didn't grind the bolt completely flush with the block. The drill walked over a little and there was some of the bolt thread left after I drilled it out. I still have my 1/4-20 helicoil set I used to fix a chopper upper bearing retainer on my first thunderbolt restoration so I drilled it with the helicoil drill and that drill followed the original hole and cleaned everything out. Now I just have to helicoil it and do a chopper test!!

Re: Thanks Bryan!!! Initial B.G.1000 findings.

Posted: Thu Jul 07, 2016 7:54 pm

by Joshua_2002

Do you have the rest of the siren?

Re: Thanks Bryan!!! Initial B.G.1000 findings.

Posted: Thu Jul 07, 2016 10:35 pm

by CDV777-1

The birds nest packed three phase blower is still up on the platform in fort worth

Re: Thanks Bryan!!! Initial B.G.1000 findings.

Posted: Thu Jul 07, 2016 10:40 pm

by Joshua_2002

Why is the blower 3 phase?

Re: Thanks Bryan!!! Initial B.G.1000 findings.

Posted: Thu Jul 07, 2016 10:43 pm

by Joshua_2002

Will the blower and controls be removed soon?

Re: Thanks Bryan!!! Initial B.G.1000 findings.

Posted: Fri Jul 08, 2016 3:44 pm

by CDV777-1

Will the blower and controls be removed soon?

No.

Re: Thanks Bryan!!! Initial B.G.1000 findings.

Posted: Fri Jul 08, 2016 3:49 pm

by connerdstines

Joshua_2002 wrote:Why is the blower 3 phase?

All series A1 Thunderbolts have three phase blowers from what i know. Single phase blowers with repulsion-start motors started being offered in the A2 series.